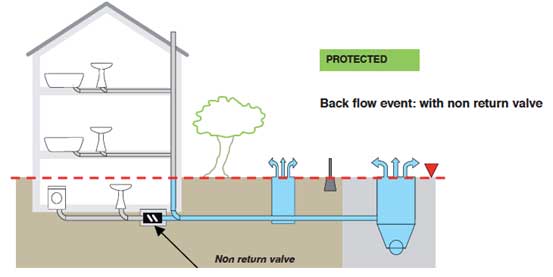

The non-return valve is active. in this case the house is protected against flood risk.

The non-return valve is active. in this case the house is protected against flood risk.

This diagram represents a typical scenario that may occur in any home with areas prone to flood risk in regards to the backflow level line. Unwanted events may take place if the sewer manifold overflows.

Backflow protection may be necessary in separate sewers, where foul and storm water flow into separate systems, and in cases of combined sewers because backflow typically indirectly involves foul water circuits due to storm water overflow. This problem is normal in areas that do not have separate systems, which concerns the majority of cases.

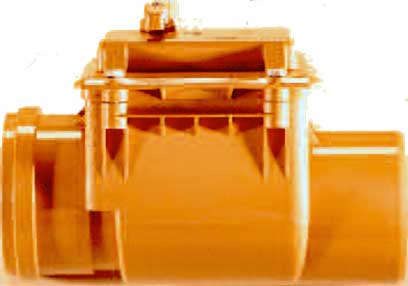

Discharge water backflow risk is simple to resolve by installing a fundamental component in new drainage systems and in modernization of existing grids - the non return Valve

Its working principle is extremely simple but also very effective.

Ottima non-return valve

The new Ottima non-return valve was designed to meet the highest technological standards on the market.

Ottima is manufactured with modern technology that ensures high product standards and reliability.

INNOVATIVE

The innovation that is expressed through its design, comprises:

- increased safety

- search for functionality

- improvement of product features

- new technical requirements

Ottima contains a series of new features that make it a sector reference product.

They are manufactured in high-stability nylon polymer for excellent resistance in time, though all parts may be replaced.

Standard Inox Flap

Standard Inox Flap

Ottima is fitted with a series of anti-rodent devices in stainless steel; therefore making it impossible for rodents to travel upwards through water pipelines.

No Metal Parts

No metal parts ensure resistance to the test of time given the lack of corrosion. All components such as screws, bolts and pins have been eliminated to ensure greater time resistance. The only metal part is the stainless steel anti-rodent device.

No Equipment Needed

Ottima poses a definitive solution to tools required for maintenance. It is designed for full inspection, disassembly and re-assembly without using special tools.

Thanks to the lever seal replacing screws and to its internal design, every part can be easily removed and repositioned without the use of special tools.

Co-Injected Gaskets

Ottima is manufactured on a production line that employs management and technology criteria market leading.

All seals, spring sheets, lids and couplings are manufactured through direct co-injection. This means that the seals are moulded directly onto the specific part. Therefore, numerous parts are eliminated, water tightness is increased, maintenance and installation are eased (no gaskets must be removed and remounted, thus eliminating assembly errors).

Stable Base

Ottima rests on a stable base that facilitates installation and level check operations. But also helps in maintenance, allowing for a stable support.

Detachable Locking Lever

Detachable Locking Lever

The locking lever is detachable. This is an important feature for installation in public-accessible areas to avoid unauthorized tampering or unwanted actuation. Should the lever be lost, the valve can be locked with a monkey wrench thanks to the hexagonal shape of the mechanism rotational axis.

Setting the locking lever in sealed position is fundamental during emergencies that require line cut-off. E.g. downstream maintenance, accidental spillage into sewers. Actuation is confirmed by the “click” sound when locked into place.

Flap Valves:

The flap valves allow the outflow of waste-water from a pipe in a drain or in a river basin, while preventing the back flow water. The particular gradient of 11° and the weight of the flap, make a reliable functioning, and allow both to open in case of discharge and close in the case of backflow.